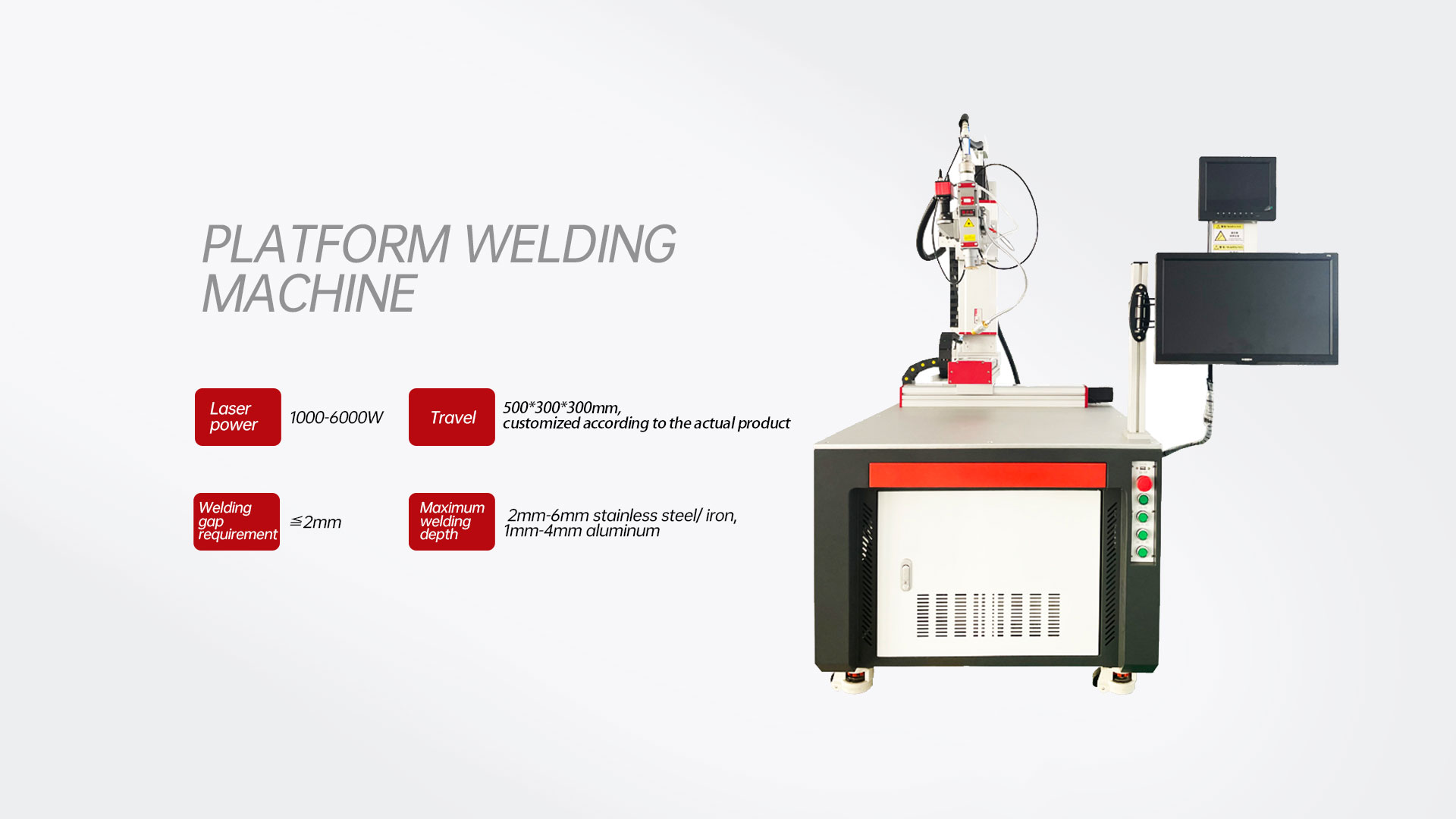

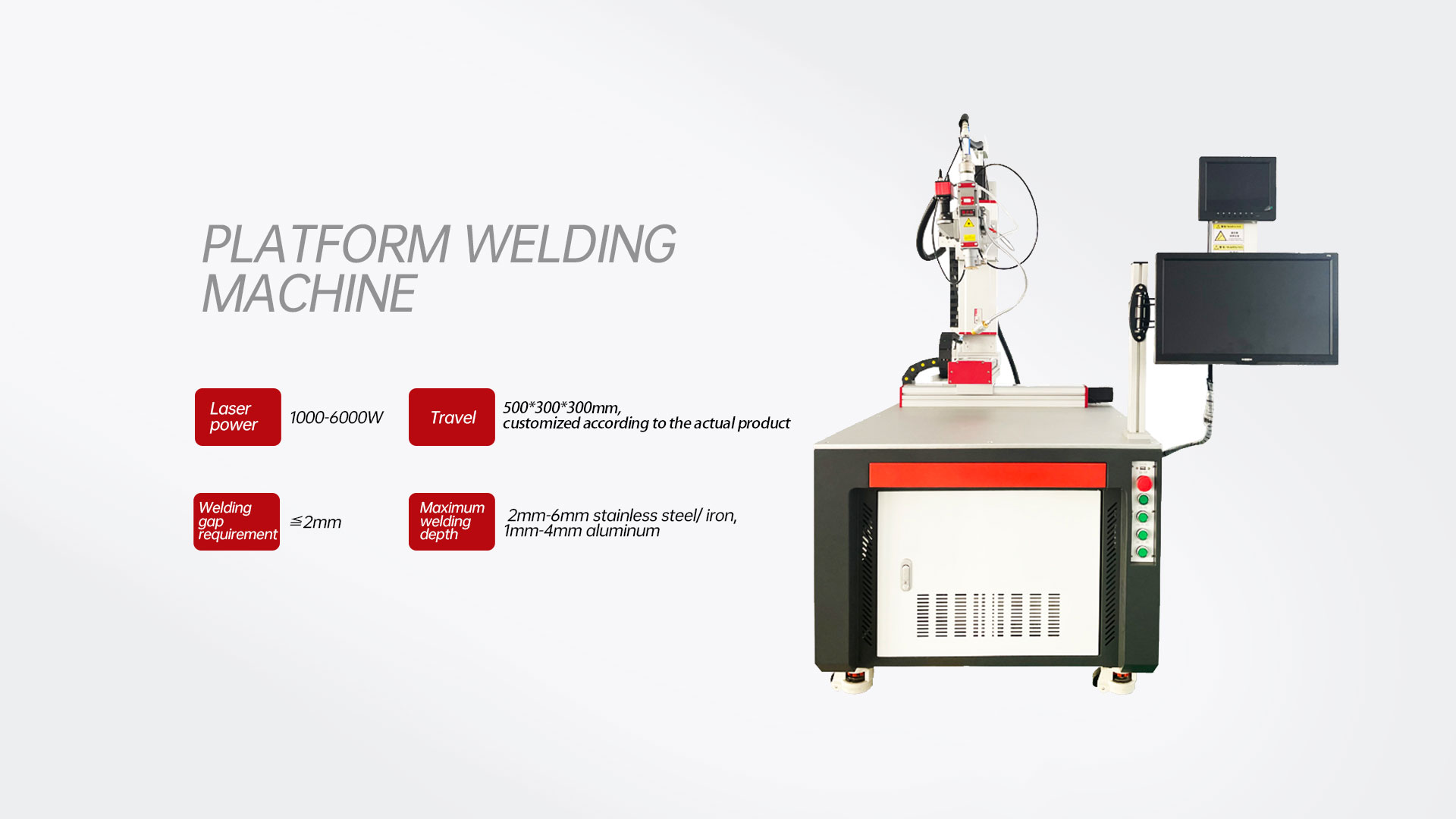

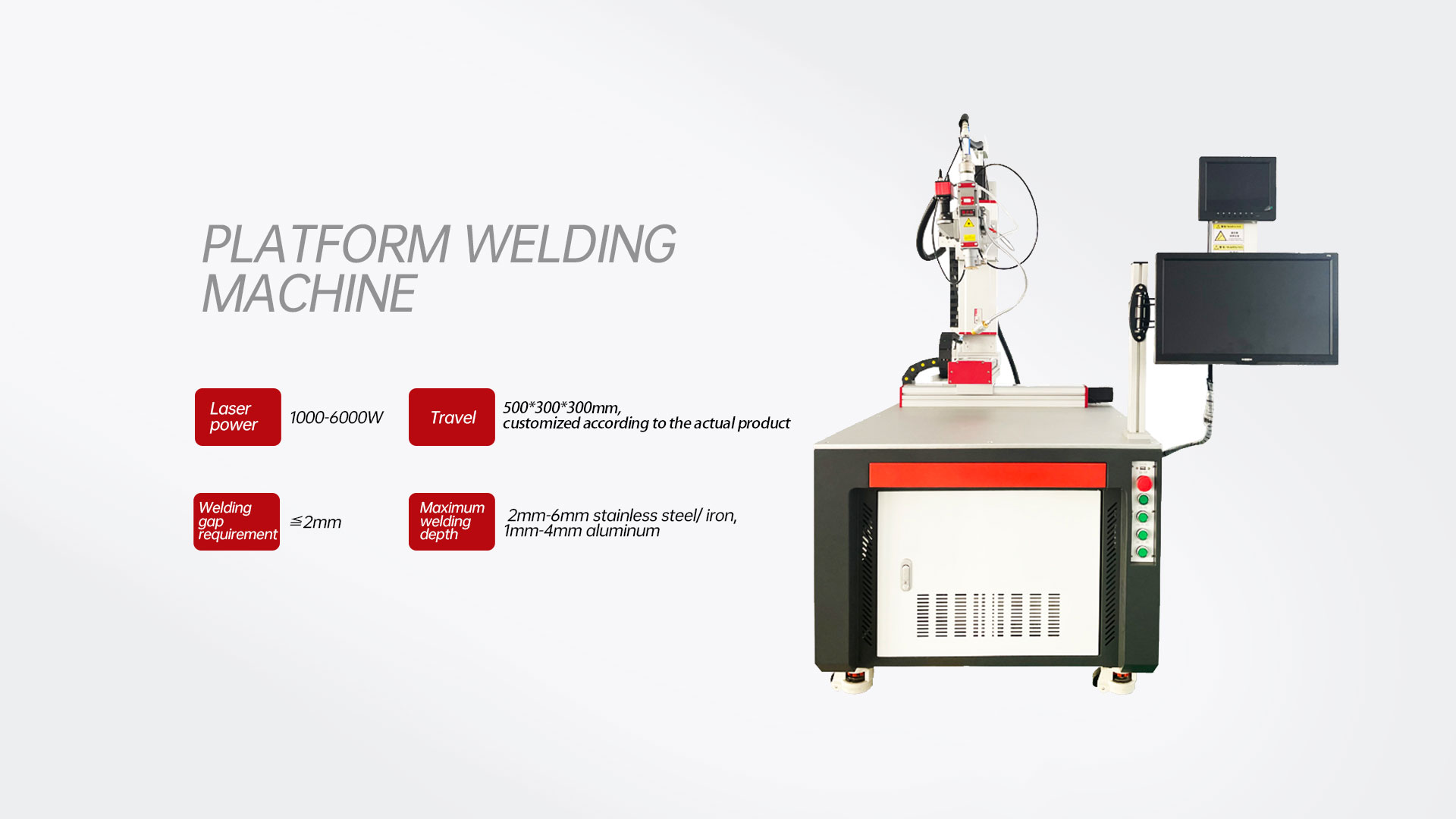

Platform Welding Machine

-

Meet special processing requirements Precise design, reliable operation.

-

Reduce labor costs and improve production efficiency.Improve working environment and reduce labor intensity.

-

Meet the requirements of automation, informatization and intelligence.

electrical components and servo drivers

It is equipped with the electrical components and servo drivers of first-line brands, such as Schneider, SMC and LEAD-MOTION to ensure that the machine is stable, reliable and responsive in operation.

Optical fiber CNC system

It is equipped with Windows operating system and optical fiber CNC system (Friendess system) with powerful functions, user-friendly interface and easy operation; the CAD/CAM can be installed in the industrial computer for drawing and programming in production, and minimizing the consumption of raw materials.

Precision cooling Hanli water tank

Precision cooling Hanli water tank is used to ensure the constant temperature of the whole machine.

Fast welding speed

There is no depression at the joint of the raised part of the molten materials in the bath and the substrate! Fast welding speed, 2-10 times faster than traditional welding speed, therefore, it can save at least 2 welders for a machine a year. Good full-material welding effect.

Long service life

Low consumption of materials. Long service life, stable power output, long-term operation.

PARAMETERS

|

model |

HYGD-AW1000/1500/2000 |

|

laser wavelength |

1070nm±10nm |

|

Introduction to laser work |

rare earth doped optical fiber |

|

pulse Width |

continuous light |

|

aiming and positioning |

red light indication+CCD |

|

control System |

linux,industrial processor |

|

travel |

500mm*300mm*300mm |

|

cooling method |

water-cooled or air-cooled |

|

optical fiber interface |

QBH |

|

fiber diameter |

50μm |

|

fiber length |

10m |

Online message

You can contact us at any time and we will provide you with comprehensive technical solution support

English

English 简体中文

简体中文