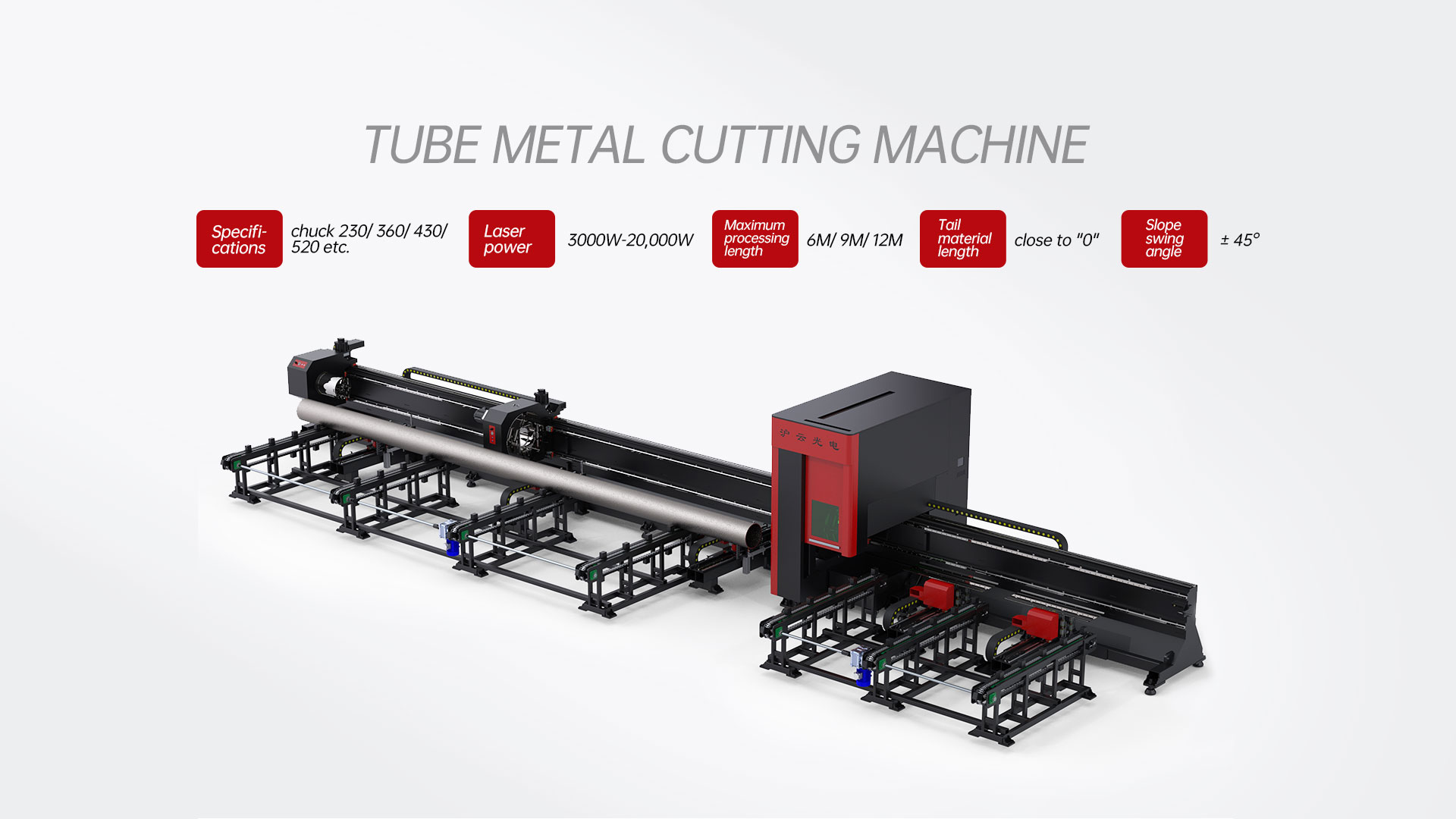

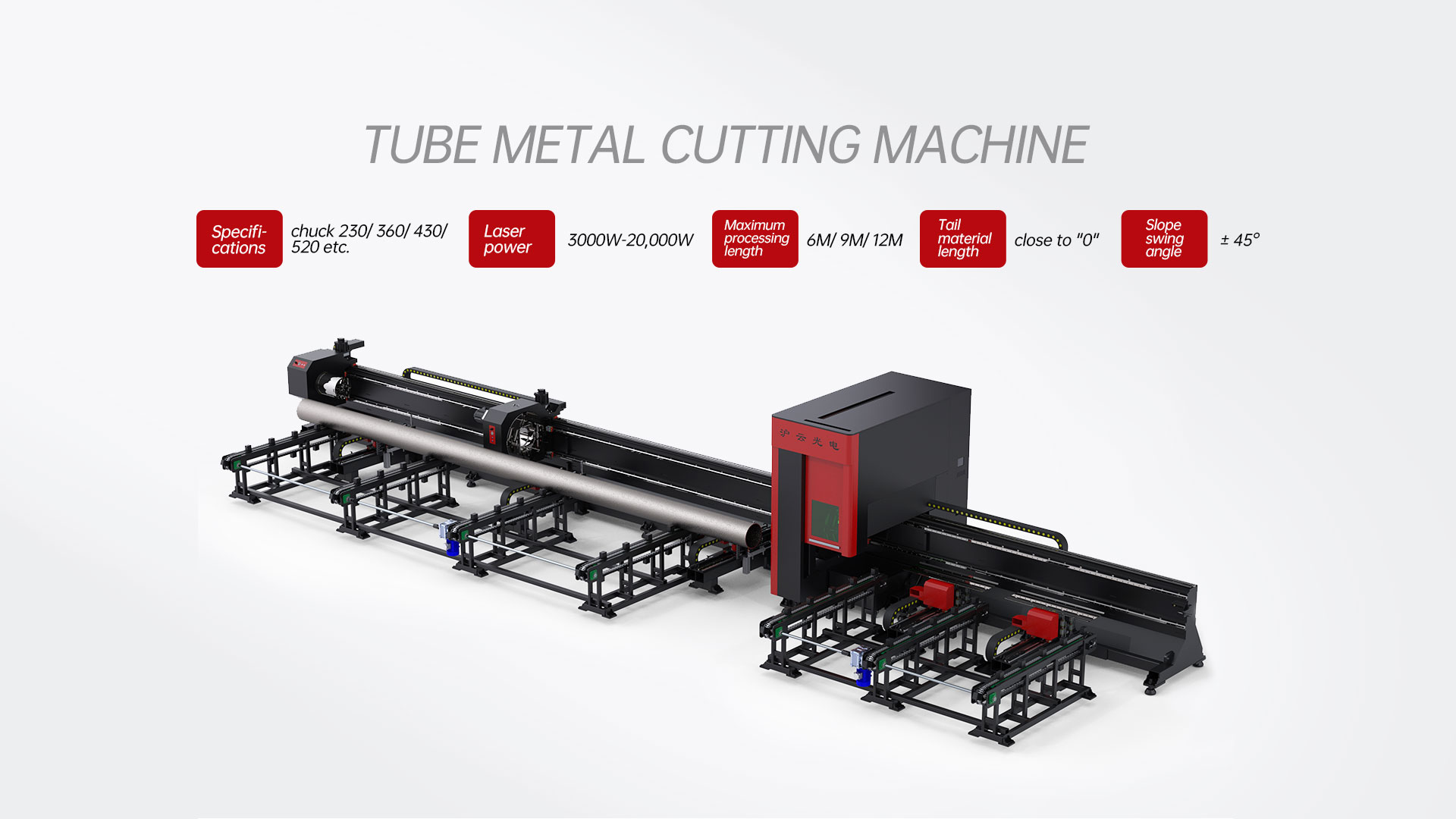

Tube Metal Cutting Machine (Triple Chucks)

-

High-end specialized equipment for processing various types of pipes.

-

Convenient loading and unloading, simple operation.

-

High precision and fast efficiency. Almost “0” tailings of cutting materials. Perfectly meet various cutting requirements for pipes.

Machine Tool Bed

The bed is made of high-strength steel in welded structure, constributing to a strong structure which is stable and firm without deformation after long-term use.。

In order to meet high-speed operation requirements, the main bed is made of high-strength steel welded and twice failure treatment to ensure the long-term operation precision and stability of the bed and excellent rigidity.

Friendess Control System

Special CNC system, realizing the cutting of tubes with different diameters in different directions; the human-computer interface is easy to operate;

Good human-computer interaction, convenient operation, standard CNC program, easy to operate for new users;

Rich process library and graphic database with process controlled at any time and quick importing of graphics;

Z-axis real-time calibration, integrating following and control units, 80% following and 20% control, realizing faster speed during turning;

Fast leapfrog, improving cutting efficiency;

High precision, high speed, high following, high intelligence;

A variety of centering methods, centering and leveling available for all kinds of pipes, thus improving cutting accuracy.

Wireless Controller

It is controlled with a wireless controller, which makes the operation more simple and efficient;

It can realize the remote control of the machine for cutting, piercing, moving, calibration and other operations.

Laser

Equipped with 3000W-12000W high and medium -power fiber laser source, it has stable performance and can be used for cutting carbon steel, stainless steel, copper, aluminum and galvanized pipes, alloy steel pipes and other metal pipes;

It presents higher photoelectric conversion efficiency, better and more stable beam quality and stronger anti-high reaction ability, and is equipped with an optimized second-generation fiber transmission system, ensuring a more stable and more precise cutting effect of thick plates;

Suitable for a variety of applications, such as cutting, welding, drilling, medical device processing; cut pipes have narrow kerf and bright section.

Pneumatic Chuck

Full-stroke pneumatic chuck, built-in cylinder, easy to install, achieving clamping and release through by air intake from sides, applicable for clamping all pipes;

The four-claw guide and guide rail mechanical transmission, realizing higher straightness and stability of four claws, and truly self-centering effect, free from position adjustment of four claws, thus greatly reducing the labor cost of adjustment, and improving production efficiency, stability and wear resistance.

Cutting Head

Auto-focus laser cutting head for optical fiber (beveling cutting);

The produt is equipped with built-in motor drive unit, the user can set continuous focusing through the program to complete the rapid perforation of thick pipes and automatic cutting of plates with different thicknesses and materials;

The product is fitted with D30 compound lens assembly for beam shaping and coupling, and the optimized optical and water-cooled design to make the laser head work stably for a long time at high power;

Advanced, contactless and high-performance motor drive technology, guaranteeing good dynamic performance;

Renishaw circular grating, full closed-loop control;

AO adaptive lens auto-focus, focus range ±10mm;

X-Y direction focus tuning unit;

TRA advanced anti-collision system can stop automatically upon accidental collision and has high self-reset accuracy;

A-axis automatic braking system can prevent bump against workpieces due to accidental power failure;

Built-in H-axis servo lifting system with a stroke of ±18.5mm;

Collimation, focusing, motor, efficient, direct and full closed loop cooling water system.

Introduction of Moving Parts

YYC, LEAN and HIWIN rack and pinion and equipped with a lock block, controlling the accuracy of the whole machine and preventing sliding; the servo motor imported from Japan, featuring high precision, high speed, stable performance and durability to ensure the high-speed and accelerated running of the whole machine.

PARAMETERS

|

performance index |

parameter |

|

cartridge |

Self-determined pneumatic chuck, 350 |

|

Applicable materials |

Not embroidered steel, carbon steel, alloy steel, copper pipe, aluminum pipe, galvanized pipe and other metal pipes |

|

Pipe type |

Round pipe, square tube, elliptical tube, rectangular tube, Angle steel, channel steel, I-steel, etc |

|

maximum machining diameter |

The tube diagonal is less than or equal to 350mm |

|

Tailor length |

0 (Different tail material length with different actual cutting materials) |

|

pendulum angle |

±45° |

|

maximum machining length |

12000mm |

|

Drain length |

6000mm |

|

positioning accuracy |

±0.1mm/m |

|

Repeat the rotation accuracy |

±0.1mm |

|

contour size of the unit |

About 20mX5.5mX3m |

|

power requirement |

380V/50HZ |

|

Complete machine power consumption |

45KVA |

Online message

You can contact us at any time and we will provide you with comprehensive technical solution support

English

English 简体中文

简体中文