The overall rigidity and strength of the main body of the equipment is high, with good acceleration performance, which can effectively prevent the deformation of the structure; The frame adopts marble structure, with good overall rigidity and high strength; Integrated structure design, compact overall layout, small footprint, good appearance quality.

RAYTOOLS, WSX, BOCI or PRECITEC fibre optic cutting head Automatic focusing; driven by imported motor, users can set up continuous focusing through the programme to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials; cartridge design to protect the lens for easy replacement.

Improve cutting quality and efficiency

-12~+10mm

Effective protection of collimating lenses

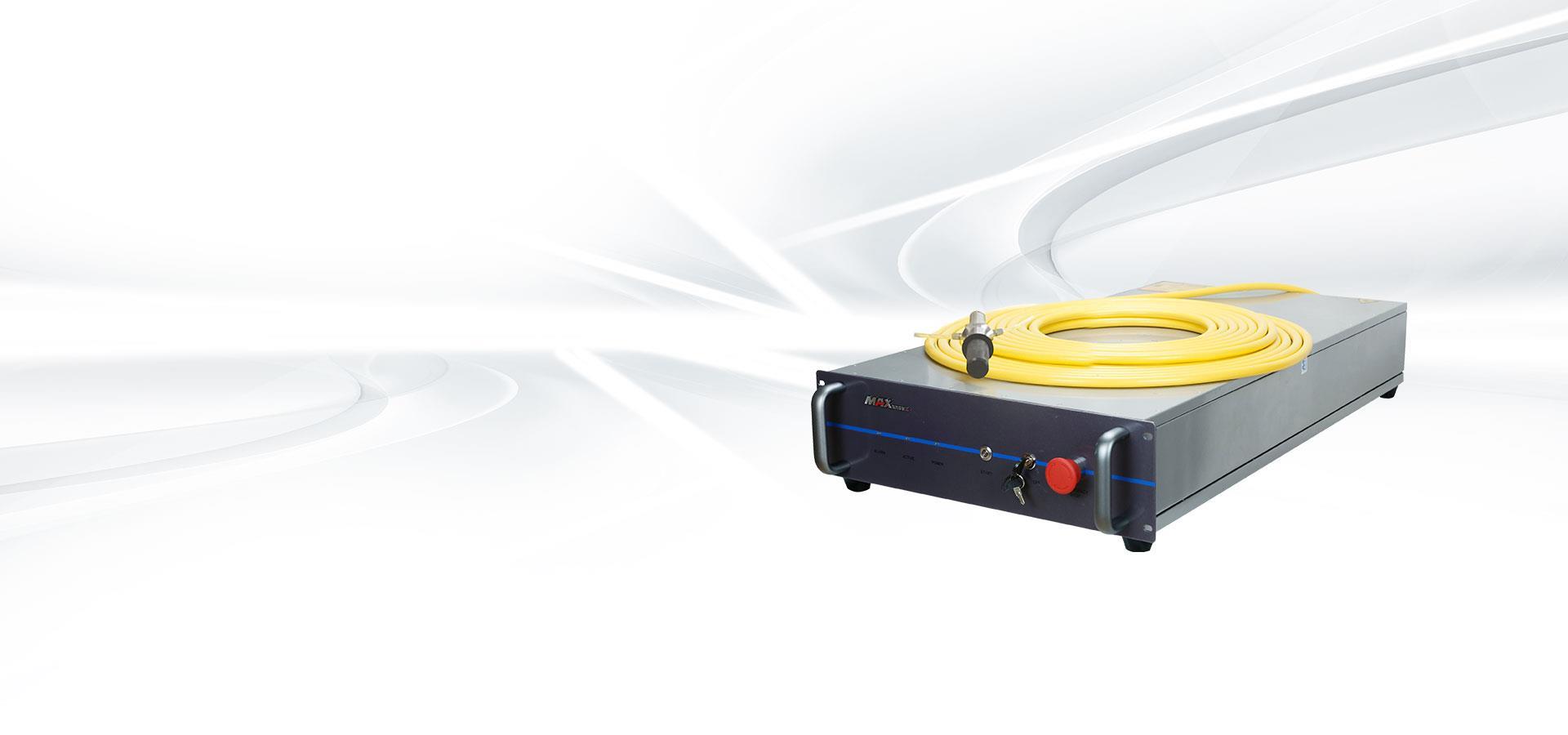

Various mainstream laser source

Adopting 1500W-6000W fibre laser sources from IPG, TRUMPF, RAYCUS, MAX PHOTONICS, RECI and BWT; the fibre laser sources have high photoelectric conversion efficiency and are equipped with optimized second-generation fibre optic transmission system for more stable beam quality and stronger resistance to high response; the cutting boards have a narrow kerf and a bright cross-section to ensure more stable and precise cutting results for thick plates

Higher single pulse energy

Thin plate welding efficient

Higher modulation frequency

Longer life

The crossbeam is made of extruded aluminium profile, which has good acceleration performance and can effectively prevent structural deformation; The crossbeam is of lightweight design with good acceleration performance and is precisely machined by CNC gantry milling machine to ensure accurate movement; The crossbeam is processed as follows: tempered to eliminate internal stresses; rough machined; subjected to two vibration failure treatments and then precision machined to ensure overall strength, stiffness and stability.

Extruded aluminium profiles

Reduction compared to other materials

Increased strength and rigidity

Resistant to corrosion and oxidation by chemical agents

Equipped with YASKAWA, HUICHUAN, FUJI, LEAD-MOTION servo motors and drives; featuring high precision, high speed, high torque, high inertia, stable and durable performance, etc., which ensures the high speed and acceleration of the whole machine.Equipped with Shimpo, Motovario, Beitto or Techmech gearboxes and YYC, LEAN or Hiwin rack and pinion for precise control and tell-tale running.

Millisecond start-up to rated speed

Low operating temperature and low noise

Encoder feedback control

Modular design

It is controlled by a wireless controller, which makes the operation simpler and more efficient; it enables remote control of the machine for cutting, piercing, moving, calibrating and other operations.

Remote control and reduced wiring

Timely response, precise control

Safe operation, stable signal

Modular design is expandable

Good human-machine interaction, easy to operate, standard CNC programme, easy for new users to operate; Rich process library and graphic database, can control the process at any time, fast import graphic; Rapid and high utilisation of nesting algorithm to reduce material waste, no upper limit on the number of nesting plates;Optimisation of cutting paths, development of a variety of general-edged tool path generation modes for different customer scenarios;High precision, high speed, high following and high intelligence; IO diagnostic function for rapid fault detection; Advanced intelligent CNC system, stable, easy to learn, efficient and fully functional.

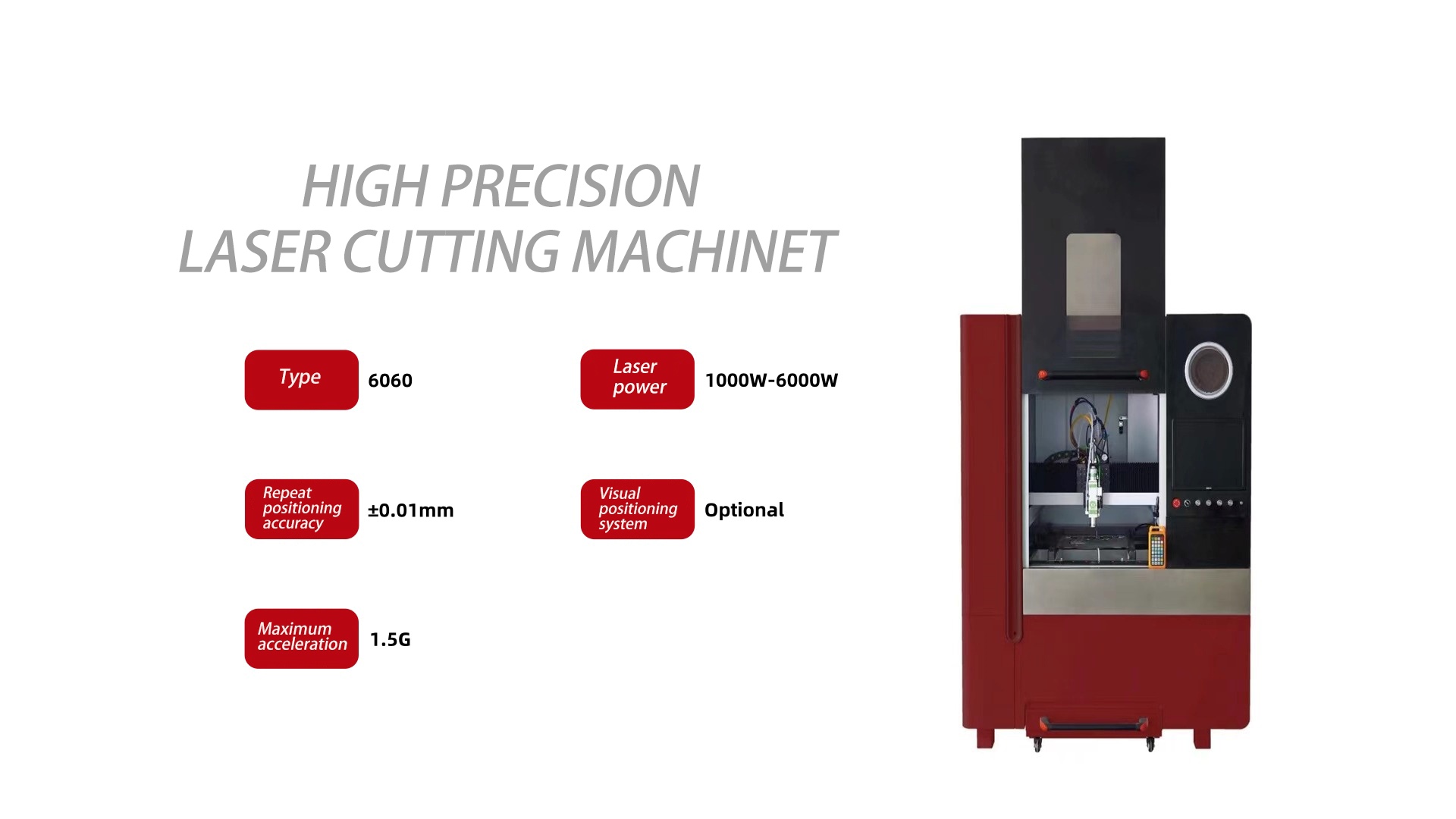

model |

HY-G6060 |

width of cloth or woolen goods |

600mm*600mm |

route or distance of travel |

600mm*600mm*100mm |

Repeat positioning accuracy |

±0.01mm |

Fast transversal speed |

60m/min |

maximal acceleration |

1.2G |

Laser power |

1000W-2000W |

Applicable materials |

Carbon steel, stainless steel, aluminum alloy, galvanized sheet and other metal materials |

Visual positioning system |

apolegamy |

Machine tool exterior size |

1400mm*1400mm*1700mm |

© tfee 1993备案号:浙ICP备17004357号-2