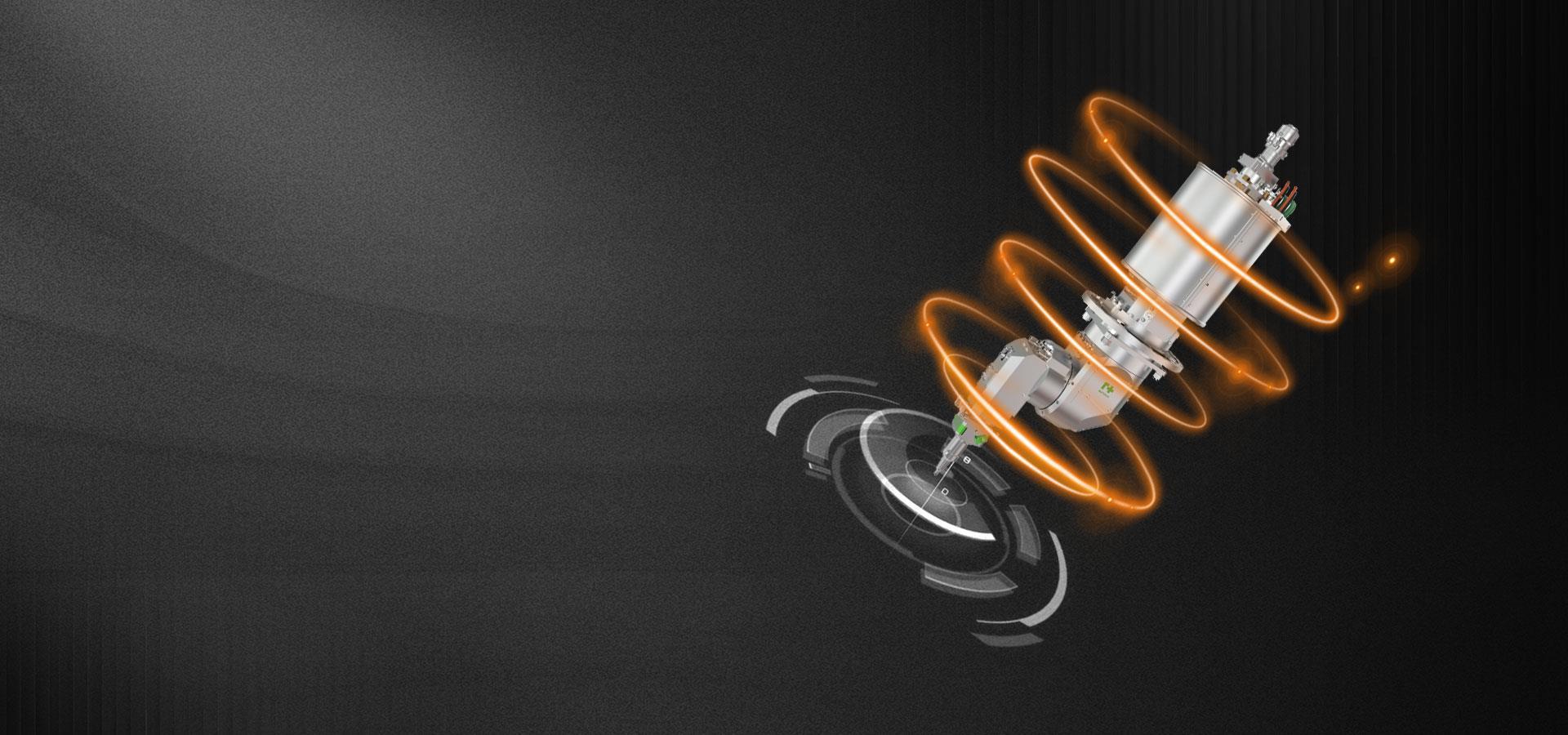

Equipped with professional 3D 5-axis laser cutting head, it can be auto-focused and multi-axis controlled to cut various 3D surfaces, which is convenient, fast and conducive to improving work efficiency.

Multi-axis linkage for flexible cutting

Perfect response to complex curves

Increased production utilisation

Aerospace and automotive precision machinery

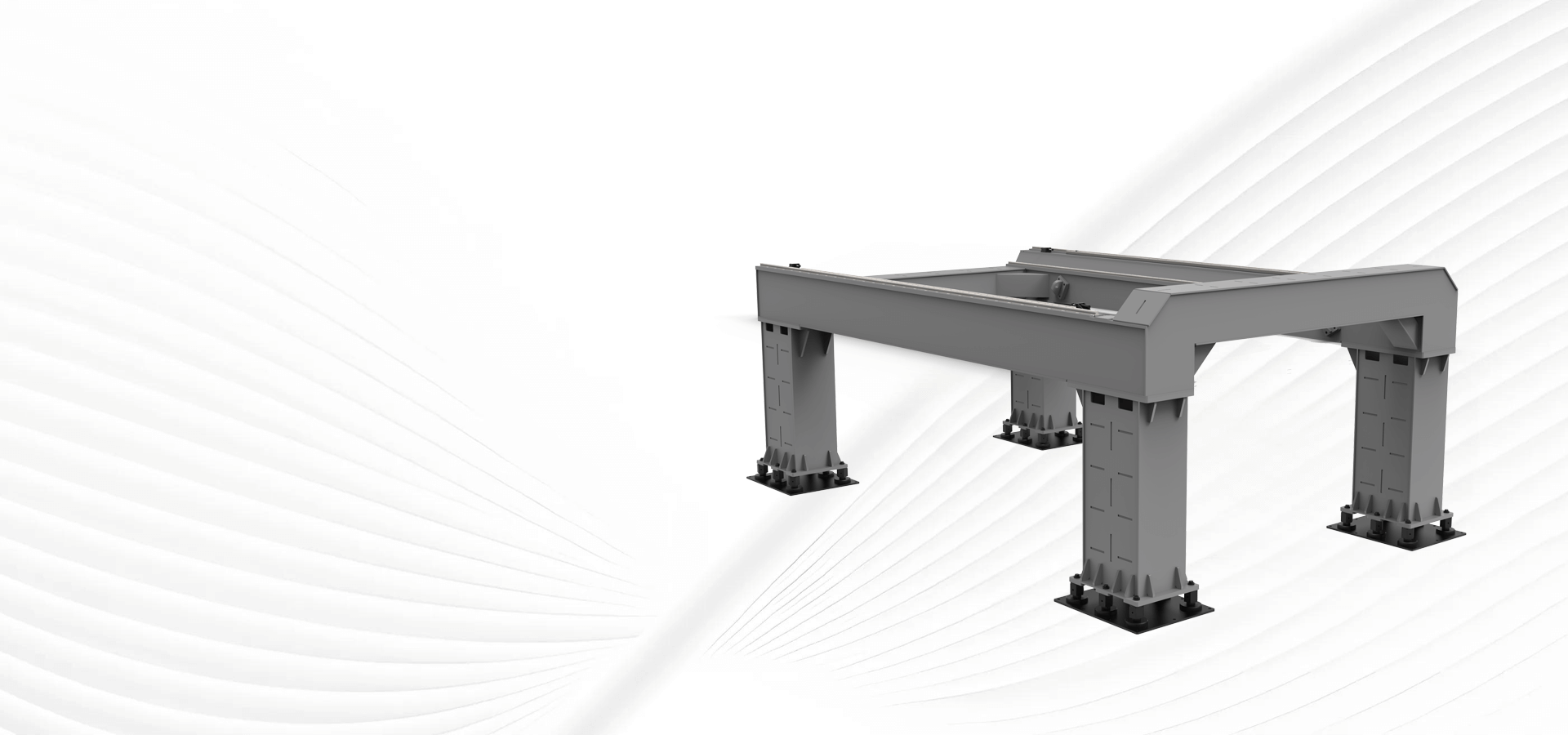

It adopts Rexroth/HIWIN guide rails, PLPHA/YYC rack and pinion, and is equipped with special compression device to control the precision of the whole machine without degradation.

Designed with bunching units

High transmission efficiency

Improved working environment

More advanced manufacturing process

The 3D laser cutting control system developed by our company is a dual control system composed of FANUC robot system and Mitsubishi PLC.

Our company developed this product based on FANUC robot application software, adding OBARA welding software and rich graphic library.

Optimisation of task allocation; seamlessness

Stable control; improved product quality

Rich functionality options

Standard design

Adopting 1500W-6000W fibre laser sources from IPG, TRUMPF, RAYCUS, MAX PHOTONICS, RECI and BWT; the fibre laser sources have high photoelectric conversion efficiency and are equipped with optimized second-generation fibre optic transmission system for more stable beam quality and stronger resistance to high response; the cutting boards have a narrow kerf and a bright cross-section to ensure more stable and precise cutting results for thick plates.

High photoelectric conversion efficiency

Enables long-distance processing

Good heat dissipation performance

Scientific structure and low maintenance cost

The bed adopts high strength steel welding structure, sturdy structure, stable and solid for long-term use, no deformation.

Adopting the standard industrial dust-proof cabinet made by Rittal from Germany, the layout is compact and reasonable, and the cabinet integrates the control board, robot IO control cabinet, laser and transformer; Adding sealing strips around the door to isolate dust entry can extend the service life of electrical components and improve the reliability and stability of machine system operation; It is equipped with a cabinet air conditioner, which keeps the temperature and humidity inside the cabinet in an ideal state at all times, thus ensuring the stable operation of the equipment.

model |

HYM-C3015PC-3000W | HYM-C6020PC-6000W |

Laser power |

3000W | 6000W |

Applicable materials |

Carbon steel, stainless steel, aluminum alloy, brass, copper violet, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy |

|

Processing area |

3000x1500mm | 6000x2000mm |

| (x * y * z) Travel trip |

3050mm*1550mm*600mm | 6050mm*2050mm*600mm |

Host weight |

About 12,500 kg | About 18,000 kg |

Main shape size |

6500x4300x2900 mm | 8500x5000x2900 mm |

© tfee 1993备案号:浙ICP备17004357号-2