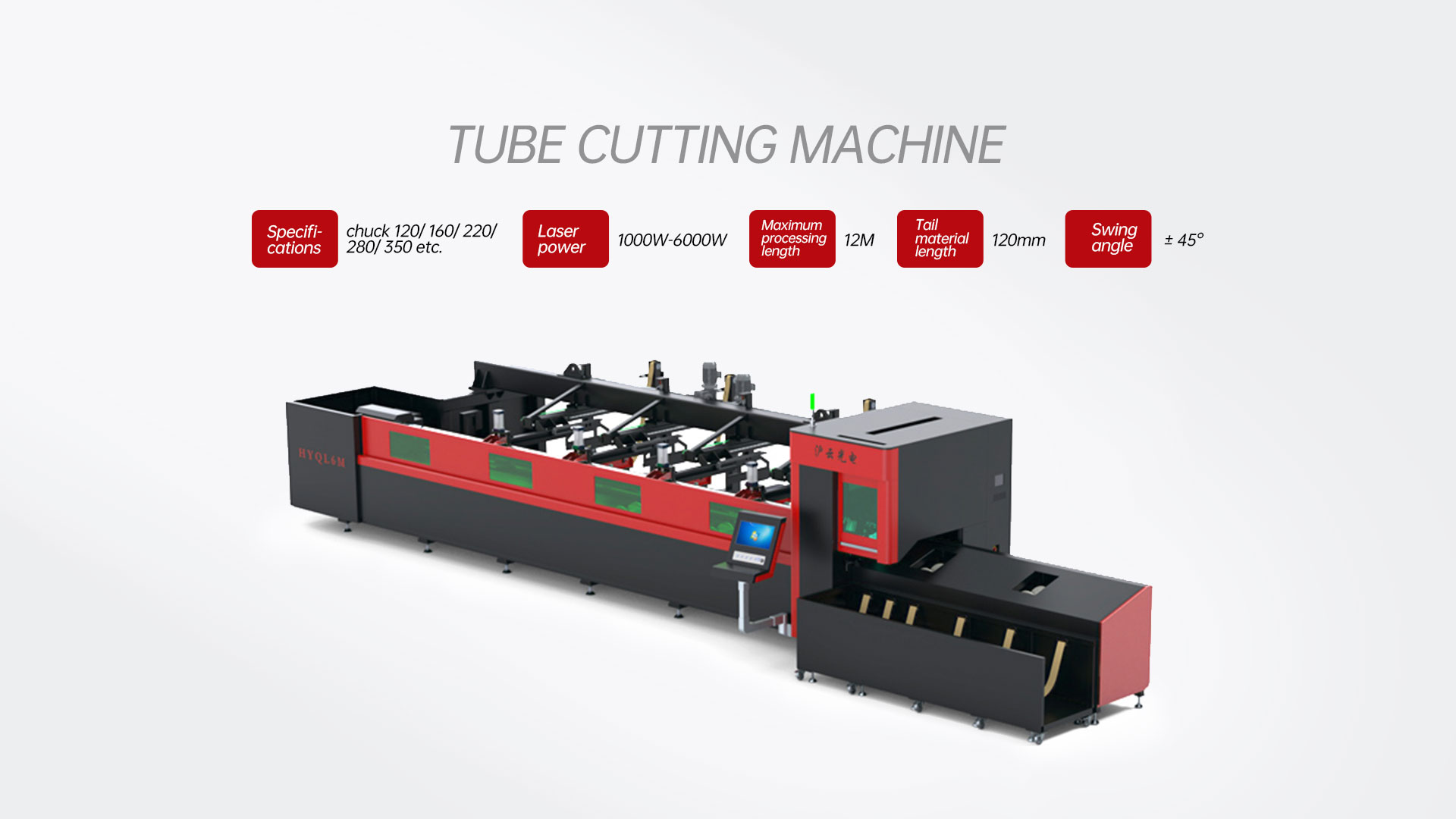

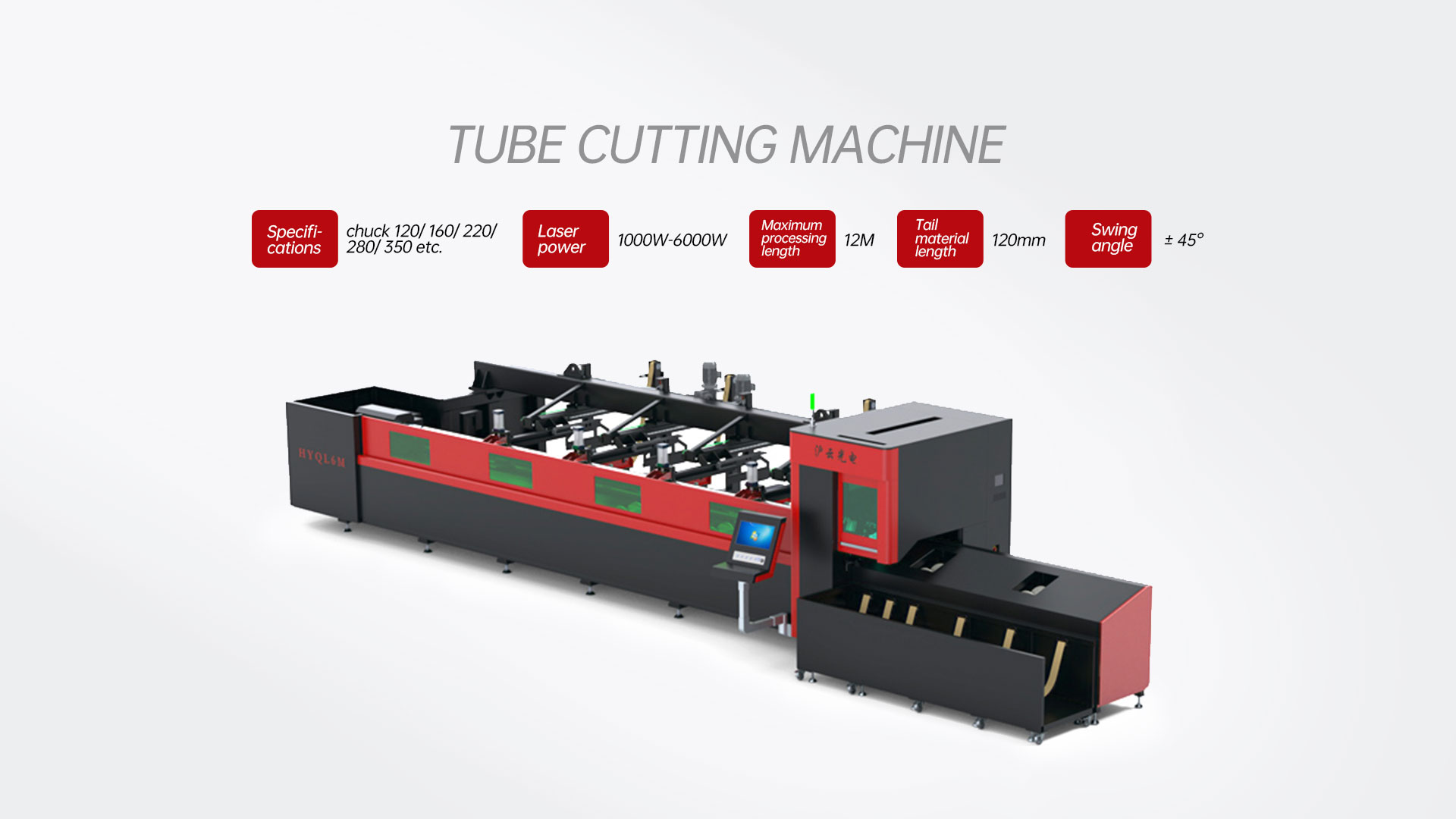

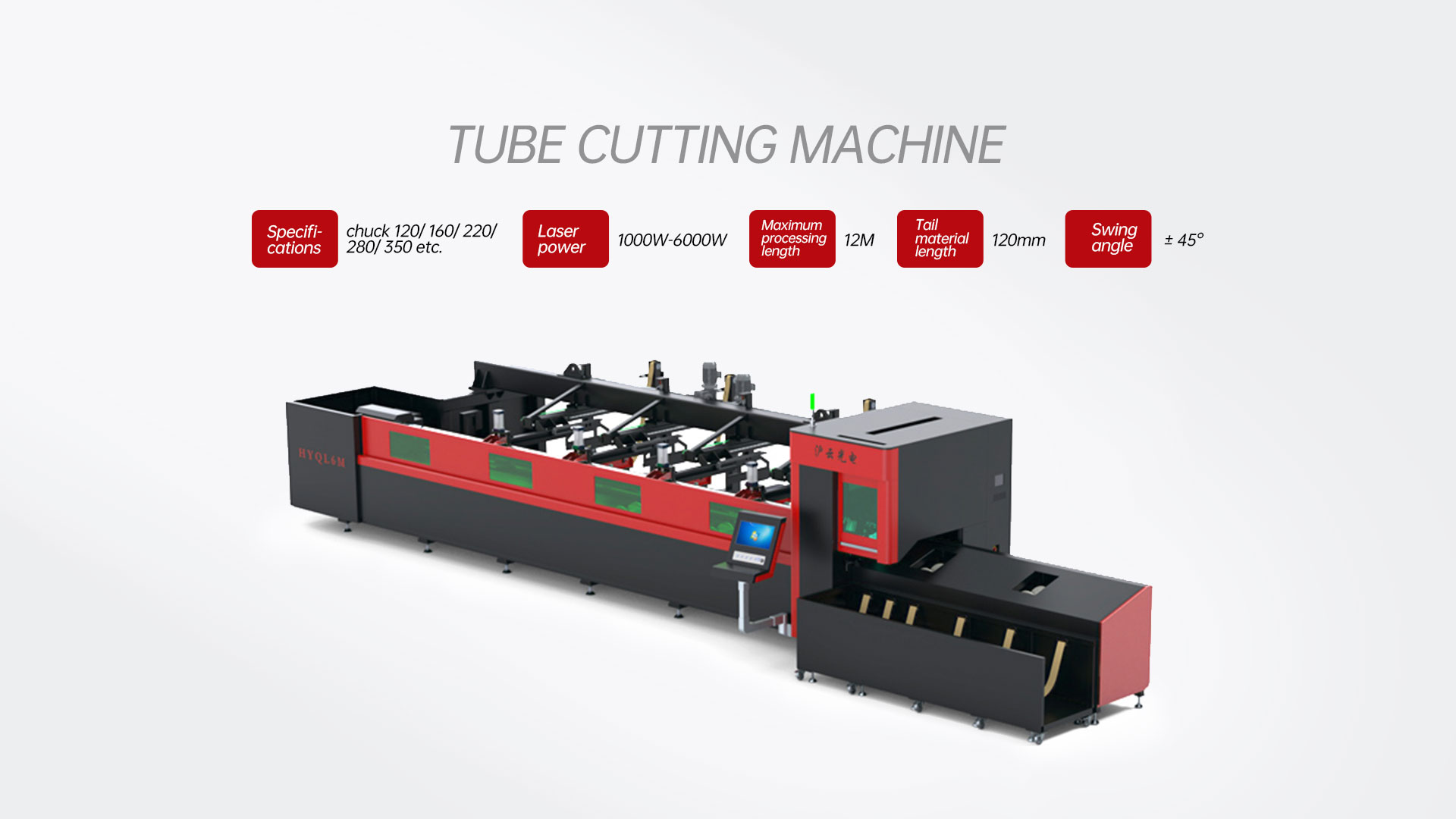

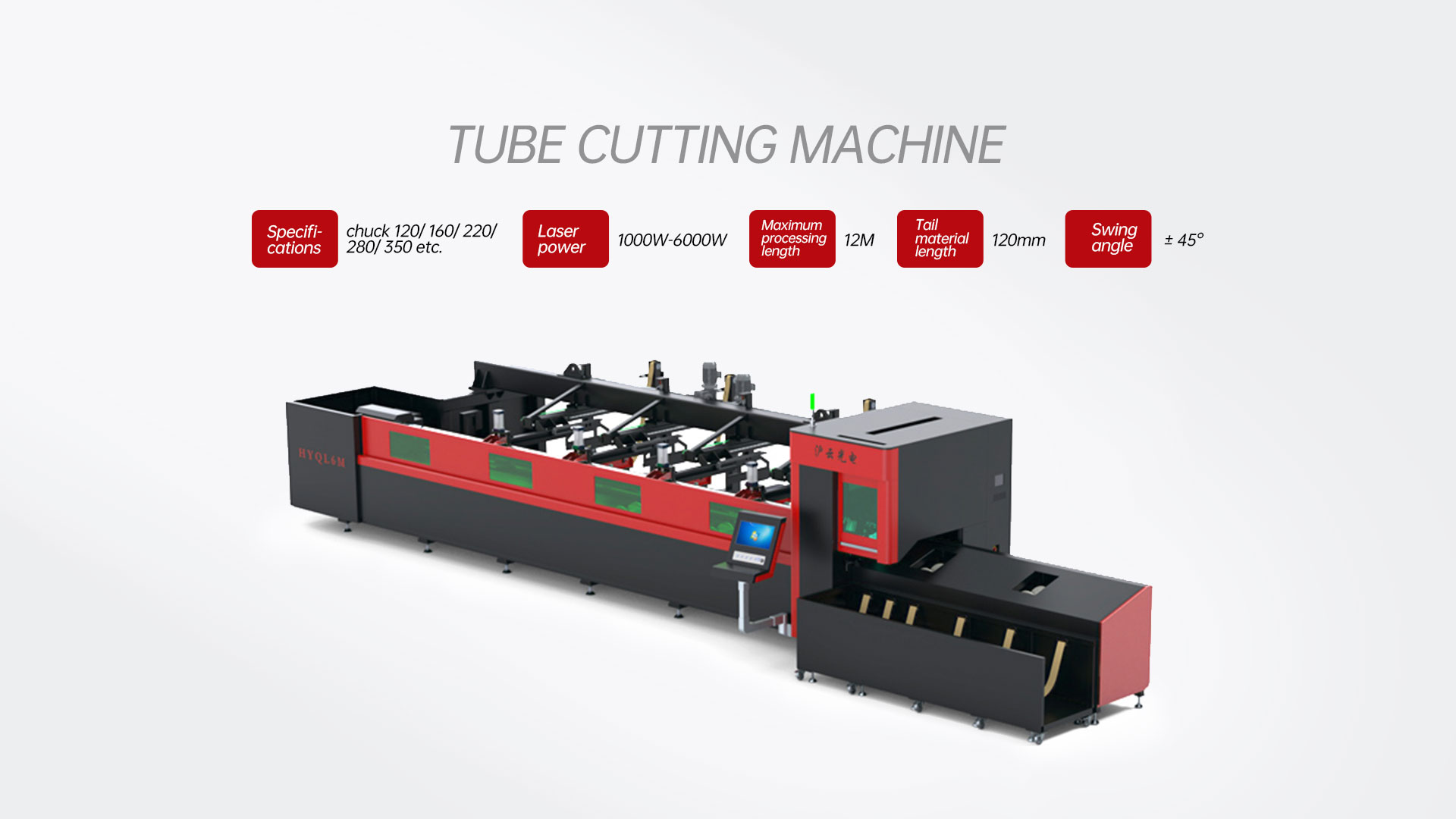

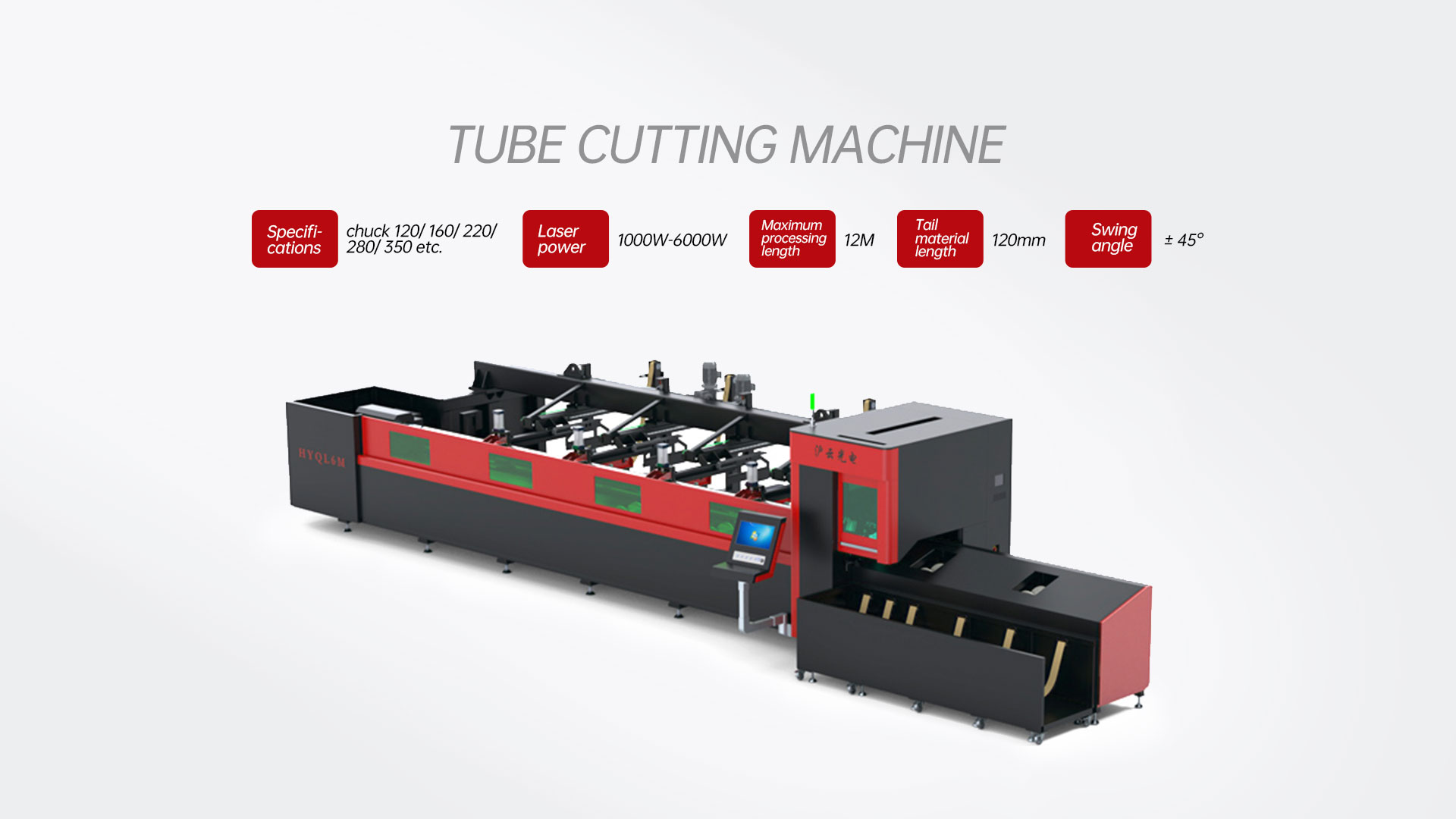

Tube Cutting Machine (Dual Chucks)

-

Suitable for processing various types of pipes.

-

Fast loading and unloading, simple operation.

-

High precision and high efficiency.

Machine Tool Bed

To address the requirements of high-speed movement, the main machine body is made of high-strength metal by welding and two failure treatments to ensure the accuracy, stability and high rigidity in long-term use.

Friendess Control System

Special CNC system, realizing the cutting of tubes with different diameters in different directions; the human-computer interface is easy to operate;

Good human-computer interaction, convenient operation, standard CNC program, easy to operate for new users;

Rich process library and graphic database with process controlled at any time and quick importing of graphics;

Z-axis real-time calibration, integrating following and control units, 80% following and 20% control, realizing faster speed during turning;

Fast leapfrog, improving cutting efficiency;

High precision, high speed, high following, high intelligence;

A variety of centering methods, centering and leveling available for all kinds of pipes, thus improving cutting accuracy.

Controlled by Wireless Controller

It is controlled with a wireless controller, which makes the operation more simple and efficient;

It can realize the remote control of the machine for cutting, piercing, moving, calibration and other operations.

Laser

It presents higher photoelectric conversion efficiency, better and more stable beam quality and stronger anti-high reaction ability, and is equipped with an optimized second-generation fiber transmission system, ensuring a more stable and more precise cutting effect of thick plates;

This product is suitable for a variety of applications, such as cutting, welding, drilling, medical device processing; cut pipes have narrow kerf and bright section.

Cutting Head

Auto-focus laser cutting head for optical fiber (beveling cutting);

The product has a built-in motor to drive the focus lens for automatic change of its position within the range of 24 mm through a linear mechanism; the user can set continuous focusing through the program to complete the rapid perforation of thick pipes and automatic cutting of pipes with different thicknesses and materials;

The product is fitted with D30 compound lens assembly for beam shaping and coupling, and the optimized optical and water-cooled design to make the laser head work stably for a long time at high power.

Pneumatic Chuck

Full-stroke pneumatic chuck, built-in cylinder, easy to install, achieving clamping and release through by air intake from sides, applicable for clamping all pipes;

The four-claw guide and guide rail mechanical transmission, realizing higher straightness and stability of four claws, and truly self-centering effect, free from position adjustment of four claws, thus greatly reducing the labor cost of adjustment, and improving production efficiency, stability and wear resistance.

PARAMETERS

|

performance index |

parameter |

|

cartridge |

Self-determined pneumatic chuck, 350 |

|

Applicable materials |

Not embroidered steel, carbon steel, alloy steel, copper pipe, aluminum pipe, galvanized pipe and other metal pipes |

|

Pipe type |

Round pipe, square tube, elliptical tube, rectangular tube, Angle steel, channel steel, I-steel, etc |

|

maximum machining diameter |

The tube diagonal is less than or equal to 350mm |

|

Tailor length |

0 (Different tail material length with different actual cutting materials) |

|

pendulum angle |

±45° |

|

maximum machining length |

12000mm |

|

Drain length |

6000mm |

|

positioning accuracy |

±0.1mm/m |

|

Repeat the rotation accuracy |

±0.1mm |

|

contour size of the unit |

About 20mX5.5mX3m |

|

power requirement |

380V/50HZ |

|

Complete machine power consumption |

45KVA |

Online message

You can contact us at any time and we will provide you with comprehensive technical solution support

English

English 简体中文

简体中文